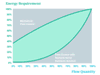

Since motors draw more than 65% of industrial power

For decades Siemens has developed drives systems that can reduce energy consumption by as much as 70%, create a return on investment in as few as 6 months, while improving end product quality, reducing production costs and lowererimg carbon emisssions.

For decades Siemens has developed drives systems that can reduce energy consumption by as much as 70%, create a return on investment in as few as 6 months, while improving end product quality, reducing production costs and lowererimg carbon emisssions.